Using a thermal imaging camera to outline electronic components enhances electronic troubleshooting. The new FLIR E4 has proved to be a hot seller for PASS Ltd, the independent test equipment professionals. One particularly enthusiastic electronics engineer uses it to monitor the temperature of circuit boards for potential faults, by finding where heat sources are on a board.

Standard optical image

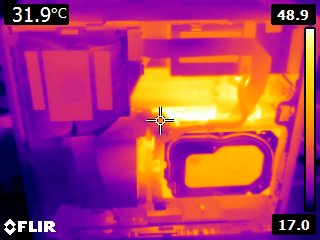

Thermal image

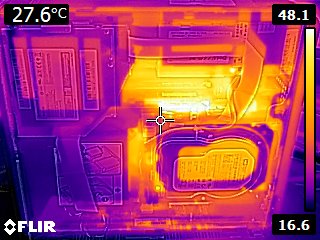

MSX-enhanced thermal image

The new FLIR E4 allows close up electronic circuit inspection without the use of lenses, while fusing the thermal spectrum with the MSX-enhanced visible spectrum images simplifies diagnostics, allowing simplified trigger action to capture images without error.

The FLIR E4 thermal imaging camera provides amazing detail for a low resolution thermal camera according to electronics engineer Fraser Castle, who holds that there is nothing particularly clever about fusing a vision image with a thermal image. However, by using outline edges, FLIR’s MSX multi-spectral dynamic imaging software adds visible spectrum detail to IR images to show the boundaries of items.

“I have used industrial thermal imaging cameras for over 20 years and historically this was the reserve of £30,000 tripod-mounted industrial thermal imaging cameras which could be heavy and unwieldy,” recalls Castle.

“The 3kg ThermaCAM PM695 was FLIR’s flagship 320 x 240 pixel medium resolution camera in the 1990s. It has served me well but I decided that it would be useful to have a simpler and more portable thermal camera for general thermal imaging tasks.

“The E4 offered me everything that I needed in a simple ‘point and capture’ thermal camera, and at a very affordable price. When it came to selecting a supplier, the company that stood out from the crowd was PASS Ltd.”

Thermal and visible spectra

Considering the E4 has a relatively low 80 x 60 pixel resolution, Castle argues that the MSX function compensates for it, allowing the user to see thermal images in context. He does not have to see the fine detail in the thermal spectrum but in the visible spectrum of an image in order to understand where the thermal energy is coming from.

With the 320 x 240 resolution PM695 camera, he needed the resolution in order to recognise the target, but a lower thermal resolution with MSX enhancement works just as well visually in his opinion.

Castle explains that with the bulkier metal-built tripod-mounted cameras of the past, higher resolution was needed for example to focus on a power distribution panel from a distance like a metre, but using a low-cost zinc selenide (ZnSe) lens such as that used on CO2 lasers would allow focussing down to a distance of 3-4cm for peering into complex electronic components.

This is not necessary with the FLIR E4, which is a fixed focus camera and whereas the PM695 has manual focussing, Castle says this is fiddly with the latter’s low depth of field. The fixed focus is an advantage because the E4 is both handheld and lightweight, and once the target is in focus a simple trigger action captures the image.

Castle adds: “With the PM695, it could be a problem getting a finger to the right button and it is nowhere near as ergonomic as the E4, which you can pull out of its pouch, switch on and within seconds you have an image - there are no complicated menus and settings.

“You had to be an experienced thermographer to get the best out of the PM695, whereas with the E4, you can be a novice who is learning about thermography.”

Castle uses thermal imaging on high density very large scale integration (VLSI) electronics where classically the failures are in the power supply circuits to capacitor banks, which glow after failure. It is also possible to see from their glow which parts of the VLSI circuitry are functioning, if a chip needs a heat sink in a board design or if regulators or drive chips are being overtaxed.

“You can immediately see the temperature profile of circuit boards, what is getting hot and how hot it is getting. This is a key benefit for anyone designing or repairing a circuit board,” Castle continues.

Stone cold chips

“I have found circuit boards where chips are stone cold – they have power but are not doing any work because the bus is faulty. Normally you would troubleshoot circuit rails by trial and error using a logic analyser but with the E4 I can spot a static chip within seconds. The E4 is the only camera I’ve seen that can do this at the price but it feels like a £5,000 camera.”

Castle was impressed with the professional attitude he encountered with PASS staff at the time of purchase, particularly senior account manager David Atkins, who was said to be very knowledgeable about thermography and the FLIR product range.

“David made the purchase of the camera as simple and pleasant as possible. A secure courier delivered my FLIR E4 on the agreed date and it was soon out of its box and working. Having used the FLIR E4 for three weeks I can confirm that it delivers all that was promised, and more. Build quality and ergonomics are truly excellent. It looks and feels like a quality product, which is what it is.

“The MSX function is invaluable, and should not be underestimated. The fusion of thermal image and visual image using MSX has been very cleverly executed to provide superb thermal images that are easy to interpret by the user and non- technical persons. Reports are easily produced by the free FLIR Tools software.

Castle concludes: “Having spoken with David Atkins at PASS several times in relation to accessories for my E4, I can also confirm that it is a most professional company with knowledgeable staff to assist customers.”

For further information please visit PASS Ltd’s dedicated thermal imaging website.